| Item |

Specifications |

| Inspection functions |

Applicable capsules |

Single-color or two-color hard capsules, printed capsules(Inspection may be limited on capsules with both transparent cap and body, or dark-color capsules.) |

| Capsule sizes |

Size 0 to Size 5 capsules |

| Inspection items |

Bright and darkness inspection: dirt, foreign particle, scratch, crack, lengthwise crack, diagonal crack, split, hole, etc.

Shape inspection: collapsed, dent, length, double capping, bent, etc.

Color inspection: color deviation, discoloration, etc.

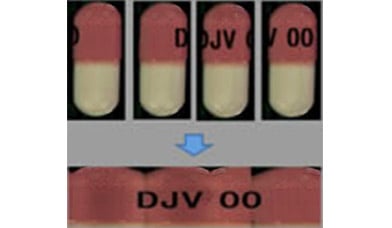

Print function: unprinted, blurred print, scratched print, etc.

Tip inspection: dirt, foreign particles, scratches, chips, collapses, dents, etc. |

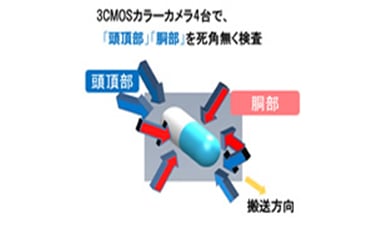

| Inspection areas |

Cap and body—whole direction and surface, head of capsule |

| Inspection accuracy |

Defects equivalent to a 50μm square or larger black speck |

| Processing capacity |

170,000–250,000 capsules/hour (may change depending on condition of capsule surface) |

| Hardware |

Image and data processing |

Optical unit |

8 Lighting Units (4 body and head)LED lighting source |

| Cameras |

3CMOS color line sensor cameras x 8 |

| Control panel |

Touch panel (data: 17 inch; control: 8.4 inch) |

| Data processing unit |

Viswill image processing unit |

| Rejection subsystem |

Rejection unit |

Pneumatic system with rejection monitoring functions |

| Defects collection box |

Capacity: 27 L |

| Uninspected collection box |

Capacity: 10 L |

| Pneumatic system |

Suction blower for the belt conveyor unit 3.7kW, Suction blower for powder collection 0.75kW |

| Software |

Inspection functions |

Individual and overall judgments; input of sensitivity; inspection condition setting; output of inspection results; simulation function |

| Diagnostic functions |

Monitoring of inspection status, monitoring of hardware, self-diagnosis |

| Size and environment |

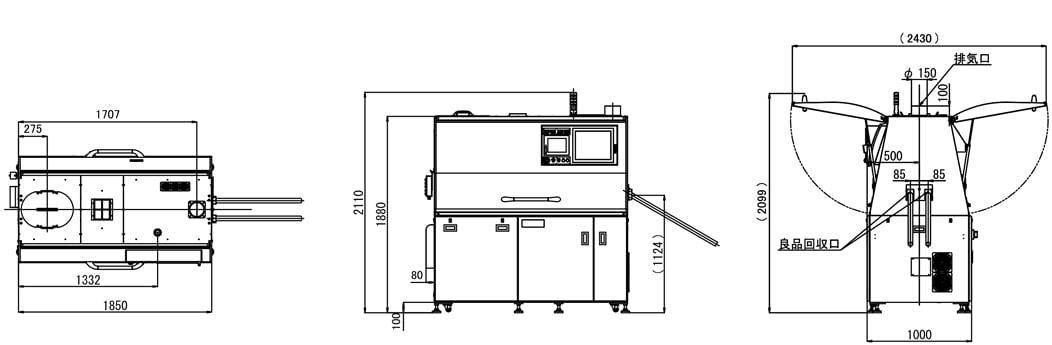

Dimensions |

1,850 (W) x 1,000 (D) x 1,880 (H) |

| Power supply |

AC 200 VAC (3 phase), 50/60 Hz |

| Power consumption |

9.0kVA |

| Pneumatic pressure |

≥ 0.5 MPa |

| Ambient conditions |

Temperature: 10–30 °C

Humidity: 30–70% |

| Exhaust air flow |

Max. 16 m3/min. |

| Exterior |

SUS304 hairline finishing |