Switch between two types of high-speed, high-precision inspections in a short period of time

- Tablet and Capsule visual inspection system

- T/CVIS-NS-V2

Tablet and Capsule visual inspection system

T/CVIS-NS-V2

Two Lines

- Tablet inspection

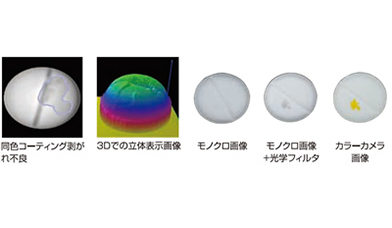

- Up to 600,000 tablets per hour of processing capacity. Equipped with high-precision 3D and color inspection, the surface condition of the tablet is faithfully reproduced, and high-precision inspection is realized.

- Tablet processing capacity

- Two Lines:

Round tablets: 600,000 tablets/hour (5 mm in diameter)

Oblong/Oval tablets: 300,000 tablets/hour (8 mm in length)

Note: May change depending on the condition of the tablet shape.

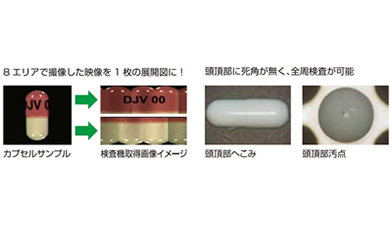

- Capsule inspection

- No blind spots in head and full-circumference inspection , as well as highly accurate printin inspection.

- Capsule Processing capacity

- Two Lines:

Size 5: Max. 250,000 capsules/hour

Size 4: Max. 235,000 capsules/hour

Size 3: Max. 220,000 capsules/hour

Size 2: Max. 200,000 capsules/hour

Size 1: Max. 185,000 capsules/hour

Size 0: Max. 170,000 capsules/hour

Note: May change depending on the condition of the capsule surface.

| Item | Specifications | ||

|---|---|---|---|

| Inspection functions | Tablets | Applicable tablets | Uncoated tablets, film-coated tablets, sugar-coated tablets, tablets with printed mark on one or both sides, scored tablets; tablets with engraved marks |

| Tablet size | Round tablets: 5–12 mm in diameter, 2–8 mm in thickness Shaped tablets: 5–12 mm in width, 2–8 mm in thickness, 5–21 mm in length Contact us for out of range tablets. | ||

| Inspection items | Dirt, scratches, foreign particles, cracks, chips, deformation, different color, discoloration, scratched print, blurred print, coating defects and emboss defects | ||

| Inspection areas | Face, back and sides | ||

| Inspection accuracy | Defects equivalent to a 50μm square or larger black speck | ||

| Processing capacity | Round tablets: 600,000 tablets/hour (5 mm in diameter) Shaped tablets: 300,000 tablets/hour (8 mm in length) |

||

| Capsules | Applicable capsules | Single-color or two-color hard capsules, printed capsules(Inspection may be limited on capsules with both transparent cap and body, or dark-color capsules.) | |

| Capsule sizes | Size 0 to Size 5 capsules | ||

| Inspection items | Bright and darkness inspection: dirt, foreign particle, scratch, crack, lengthwise crack, diagonal crack, split, hole, etc. Shape inspection: collapsed, dent, length, double capping, bent, etc. Color inspection: color deviation, discoloration, etc. Print function: unprinted, blurred print, scratched print, etc. Tip inspection: dirt, foreign particles, scratches, chips, collapses, dents, etc. |

||

| Inspection areas | Cap and body—whole direction and surface, head of capsule | ||

| Inspection accuracy | Defects equivalent to a 50μm square or larger black speck | ||

| Processing capacity | 170,000–250,000 capsules/hour (may change depending on condition of capsule surface) | ||

| Hardware | Image and data processing | Optical unit | Face/side lighting unit (LED) and 3D inspection unit (laser) |

| Cameras | 3CMOS color line sensor cameras x 8, CMOS area sensor cameras x 4 | ||

| Communication | Touch panel | ||

| Image processing unit | Viswill Image Processing Unit | ||

| Rejection subsystem | Rejection unit | Pneumatic system with rejection monitoring functions | |

| Defects collection box | Capacity: 27 L | ||

| Uninspected collection box | Capacity: 10 L | ||

| Pneumatic system | Suction blower for the bel conveyor (2.2 kW), Suction blower for powder collection (0.75 kW), Suction bolowr blower for the lamp cooling (0.4 kW) | ||

| Software | Inspection functions | Individual and overall judgments; input of sensitivity; inspection condition setting; output of inspection results; simulation function | |

| Diagnostic functions | Monitoring of inspection status, monitoring of hardware, self-diagnosis | ||

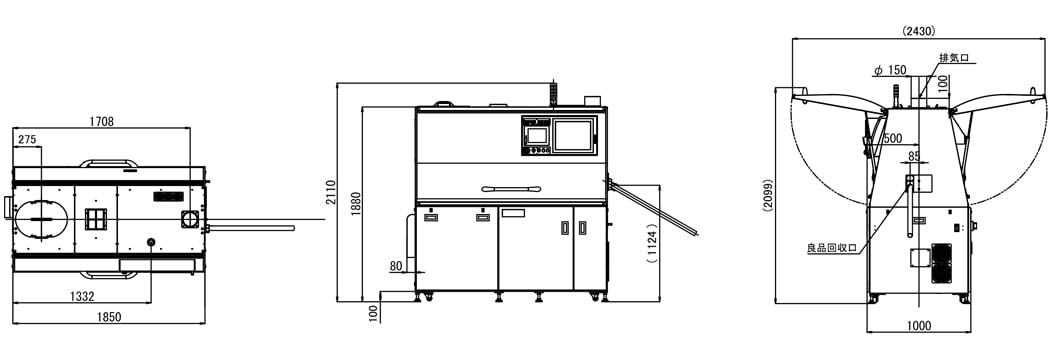

| Size and environment | Dimensions | 1,850 (W) x 1,000 (D) x 1,880 (H) | |

| Power supply | AC 200 VAC (3 phase), 50/60 Hz | ||

| Power consumption | 9.0kVA | ||

| Pneumatic pressure | ≥ 0.5 MPa | ||

| Ambient conditions | Temperature: 10–30 °C Humidity: 30–70% |

||

| Exhaust air flow | Max. 16 m3/min. | ||

| Exterior | SUS304 hairline finishing | ||