Evolved Tablet Visual Inspection System(NS-VA Series)

- Tablet Visual Inspection System

- TVIS-NS-VA1

Tablet Visual Inspection System

TVIS-NS-VA1

One Line

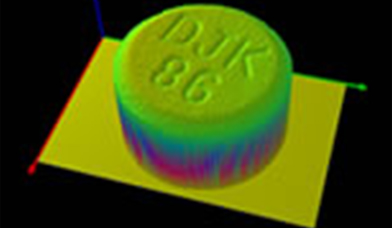

- High-accuracy 3D inspection (Nakai Prize winner)

- It is possible to detect small chipping that were difficult to detect by conventional methods at high speed.

We are recognized for our high level of contribution to quality assurance and productivity improvement in the pharmaceutical manufacturing process, we won the Nakai Prize of the Japan Society of Pharmaceutical Machinery and Engineering, the highest in the industry.

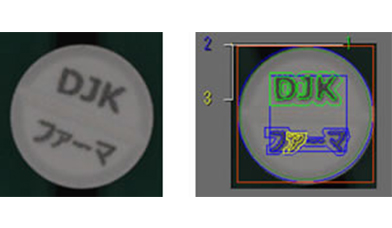

- High-accuracy character inspection VCR

-

The labeling inspection, which inspects printing/emboss one character at a time, has been further evolved. High-speed processing of pattern matching that can optionally set the area of interest (ROI) enables more accurate character inspection.

As shown at right, it is possible to detect the words "DJK" and "ファーマ" overall, as well as the individual character "ァ" in "ファーマ".

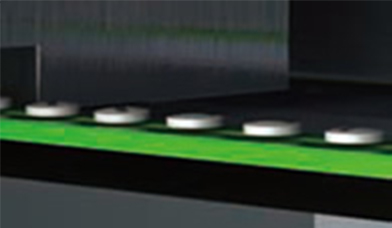

- Stable transfer/increased processing capability

-

We have accumulated experience and experience in simple mechanisms of trough unit, flow control unit, and disk-track rotation methods. And then we are making it possible to achieve higher and more stable processing capacity.

One Line:

Round tablets: 300,000 tablets/hour (5 mm in diameter)

Shaped tablets: 150,000 tablets/hour (8 mm in length)

- Equipped with image processing system V-IPU

-

HMI, work control, and image processing are integrated into one unit to achieve highly accurate, high-speed image processing.

Using an extensive image processing library, by inspecting the area image, which is an image of one tablet of each line image, it has become possible to detect defective features that were difficult to detect in the past.

| Item | Specifications | ||

|---|---|---|---|

| Inspection functions | Applicable tablets | Uncoated tablets, film-coated tablets, sugar-coated tablets, multilayer tablets Tablets with printed marks on one or both sides; scored tablets; tablets with engraved marks | |

| Tablet size | Round tablets: 5–12 mm in diameter, 2–8 mm in thickness Oblong/Oval tablets: 5–12 mm in width, 2–8 mm in thickness, 5–21 mm in length Contact us for out of range tablets. | ||

| Inspection items | Dirt, scratches, foreign particles, cracks, chips, deformation, different color, discoloration, scratched print, blurred print, coating defects and emboss defects | ||

| Inspection areas | Face, back, and sides | ||

| Inspection accuracy | Defects equivalent to a 50μm square or larger black speck | ||

| Processing capacity | Round tablets: 300,000 tablets/hour (5 mm in diameter) Shaped tablets: 150,000 tablets/hour (8 mm in length) |

||

| Hardware | Image and data processing | Optical unit | Face/side lighting unit (LED) and 3D inspection unit (laser) |

| Cameras | 3CMOS color line sensor camera x 2, CMOS area sensor camera x 2 |

||

| Communication | Touch panel | ||

| Data processing unit | Viswill Image Processing Unit | ||

| Rejection subsystem | Rejection unit | Pneumatic system with rejection monitoring functions | |

| Defects collection box | Capacity: 27 L | ||

| Uninspected collection box | Capacity: 10 L | ||

| Pneumatic system | Suction blower for the belt conveyor unit 3.7kW, Suction blower for powder collection 0.75kW | ||

| Software | Inspection functions | Individual and overall judgments; input of sensitivity; inspection condition setting; output of inspection results; simulation function | |

| Diagnostic functions | Monitoring of inspection status, monitoring of hardware, self-diagnosis | ||

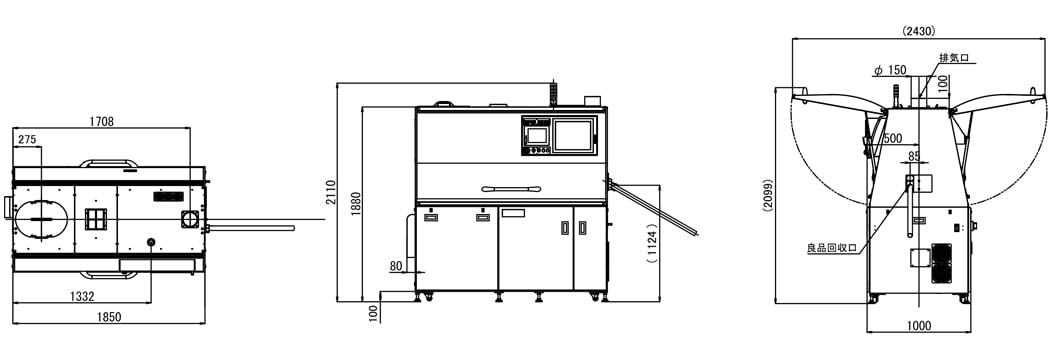

| Size and environment | Dimensions | 1,850 (W) x 1,000 (D) x 1,880 (H) | |

| Weight | 1,300kg | ||

| Power supply | AC 200 VAC (3 phase), 50/60 Hz | ||

| Power consumption | 9.0kVA | ||

| Pneumatic pressure | ≥ 0.5 MPa | ||

| Ambient conditions | Temperature: 10–30 °C Humidity: 30–70% |

||

| Exhaust air flow | Max. 16 m3/min. | ||

| Exterior | SUS304 hairline finishing | ||